Genentech has put a clear position on biosimilars on its website. The company explains that the terms ‘biosimilar’ or ‘follow-on biologic’ refer to products that are marketed after expiration of patents, which are claimed to have similar properties to existing biological products. Due to the complexity of biologicals, a product can only be made that is similar, but not identical.

Keeping safety in mind, Genentech believes that each clinical indication for a biosimilar should be established by indication-specific clinical trials to ensure the safety and efficacy of the biosimilar; biosimilars should only be substituted for an innovator biological if comparative clinical trials demonstrate that substitution is appropriate; and biosimilars should be uniquely identified and should be traceable to ensure patient safety.

Background

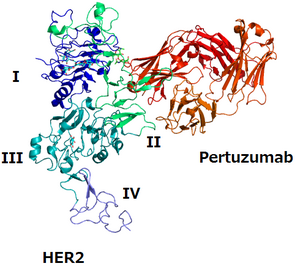

Many small molecule drugs can be taken orally, and tend to work in the body within cells. Since biologicals are significantly larger in size, they are typically injected and interact within the body in the bloodstream or on the surfaces of cells, rather than within the cells. In contrast, small molecule drugs are typically composed of only 20 to 100 atoms. Small biologicals, such as hormones, are typically composed of 200 to 3,000 atoms, while large biologicals, such as antibodies, are typically composed of 5,000 to 50,000 atoms.

Manufacturing processes for biologicals differ greatly from the manufacturing processes for small molecule drugs. Small molecule drugs are generally synthesised using chemical reactions. Biologicals, by comparison, are typically produced within specially engineered cells. Small molecules are well-characterised, and can be easily purified and analysed with routine laboratory tests. Biologicals, especially larger biologicals tend to be produced as diverse mixtures of molecules that differ very slightly from one another, which make them difficult to characterise. It follows that the properties of the biologicals often depend directly on the nature of the manufacturing process. Furthermore, proteins have unique structural organisation patterns (referred to as ‘folding’) that affect the way that they work in the body; even biologicals that are chemically the same may have differing biological effects due to differences in the structural folding. An example of this folding effect is the difference between a raw egg and a cooked one: chemically the two are the same, but they are physically and biologically very different.

Patient safety

Genentech believes that because of the differences between biologicals, challenging issues exist relating to the development, approval and marketing of biosimilar products. Genentech further believes that patient safety must be of paramount consideration when evaluating these issues.

Need for clinical trials and indication specific approval

Due to the complexity of biologicals as well as the distinctions introduced by differing manufacturing processes, Genentech believes that each biosimilar must be shown to be safe and effective on the basis of its own adequate and well-controlled clinical studies. Genentech also believes that biosimilar products should only be approved initially for the indication that is directly supported by the non-clinical and clinical safety and efficacy data package submitted by the sponsor. When an innovator product has been approved for more than one indication, any biosimilar product should likewise be studied in each indication to support approval.

No automatic substitution/interchangeability

In addition, Genentech believes that the differing manufacturing processes mean that each biosimilar is likely to be inherently different from the corresponding innovator biological. As such, pharmacists should not be allowed to freely substitute the follow-on biologic for the innovator's product. Rather, Genentech believes that substitution may only be possible if the sponsor performs adequate comparative clinical trials to establish that its product acts the same as (rather than similar to) the innovator product in the body and the treating physician agrees to prescribe the biosimilar.

Product identification and traceability

Biotechnology-derived products are complex proteins that are extremely difficult for even the innovator to manufacture. Minor changes in the manufacturing process can inadvertently result in significant and possibly dangerous differences to the final product. Therefore, it is critical that products administered to patients be identifiable and traceable back to the manufacturer. Patient safety interests require that adverse events be quickly and accurately correlated with the actual product administered. This correlation is essential to allow for immediate action to recall products when manufacturing processes resulted in a product causing patients to experience adverse events.

Post-marketing risk management plans required

Post-marketing risk management plans must be an essential element of any approval of a biosimilar product. Although Genentech believes that follow on products must contain their own adequate and well-controlled trials, the company recognises that because they would be approved based in part on the prior approval of the innovator product, sponsors might be allowed to submit less data than that of the innovator to support approval of their products. As such, biosimilar manufacturers would have less experience with their products upon approval. In order to protect patients from products with less complete data packages, Genentech believes that continued assessment of the product after approval is necessary, and recommends that biosimilar sponsors be required to have risk management plans in place to compensate for this gap in data by collecting the additional necessary experiential information.

Similarity and comparability are distinct concepts

In addition, Genentech believes that the concepts of similarity and comparability are distinct and must be properly applied to any approval process of a biosimilar product. Manufacturers of innovator products are permitted to make post-approval manufacturing changes to their products based upon a showing of comparability between the two products. This approach is appropriate because innovator manufacturers possess a thorough and robust body of knowledge about the process used to manufacture the original product, which can be applied in support of subsequent modifications to the manufacturing process. In contrast, a biosimilar product would be approved based on an analytical determination that the product is similar to the innovator product. Due to the importance of trade secret protections, the biosimilar sponsor would not have access to the cell line or the critical manufacturing processes that are essential to production of the innovator product. As a result, new clinical data will be needed to support similarity to an innovator product. Furthermore a complete analytical comparison with the reference product is necessary to support approval of a biosimilar.

No reliance on trade secret or confidential commercial information

Finally, Genentech believes that regulatory agencies should not refer to or rely on innovator trade secrets and confidential commercial information to approve a biosimilar product.

Genentech will continue to encourage and participate in public discussions of the technical and legal complexities involved with establishing an approval pathway for biosimilars in the US.

Source: Genentech (http://www.gene.com/gene/about/views/followon-biologics.html)

0

0

Post your comment