Canada-based PlantForm have altered tobacco plants to create a biosimilar version of Roche’s breast cancer drug Herceptin (trastuzumab).

Biosimilar trastuzumab made in tobacco plants

Biosimilars/News

|

Posted 18/01/2013

0

Post your comment

0

Post your comment

The company licensed the technology from the University of Guelph in Ontario, Canada, where it was developed by Dr J Christopher Hall, the Canada Research Chair in Recombinant Antibody Technology.

The brand-name drug, Herceptin, is currently produced in animal cells, which is complicated and expensive. Tobacco plants, on the other hand, grow quickly and their biology is well-known by scientists. Humans and tobacco plants also have the same cell system. Since these plants just require water and sunlight to grow it is a much cheaper way to produce the drug.

This is not the first time plant technology has been used to create biosimilars. During 2011–2012 monoclonal antibody biosimilars, palivizumab and rituximab, were produced in non-transgenic green plants by biotechnology company iBio [1, 2].

An efficacy study in mice has shown that PlantForm’s biosimilar trastuzumab antibody drug is as effective as Herceptin in reducing the size and growth rate of breast cancer tumours.

The next step for the company is to carry out clinical trials in humans, which are expected to begin in 2014. PlantForm then expects to launch its biosimilar trastuzumab, in partnership with a pharmaceutical company, in world markets in 2016.

Herceptin has sales of C$6 billion annually and treatment with Herceptin can cost as much as C$100,000 per patient per year, according to PlantForm. The brand-name drug will lose patent protection in the EU in 2014 and in the US in 2017, causing PlantForm to focus its efforts first on Europe. PlantForm expects its plant-based production system to lower manufacturing costs by as much as 90%, making the biosimilar an affordable alternative.

The total market potential for all biosimilar trastuzumab products is estimated by PlantForm to be C$2 billion a year by 2016 and C$4–5 billion a year by 2019.

PlantForm’s technology platform is capable of producing a wide range of biopharmaceutical products, including monoclonal antibodies, protein drugs and vaccines. PlantForm is also developing biosimilar versions of two additional cancer drugs that have combined annual global sales of C$11.4 billion.

Related articles

Pfizer carrying out biosimilar trastuzumab trial in US

US$67 billion worth of biosimilar patents expiring before 2020

References

1. GaBI Online - Generics and Biosimilars Initiative. Also noted on biosimilars: 13 April 2012: Palivizumab biosimilar successfully produced in plants [www.gabionline.net]. Mol, Belgium: Pro Pharma Communications International; [cited 2013 Jan 18]. Available from: www.gabionline.net/Biosimilars/General/Also-noted-on-biosimilars-13-April-2012

2. GaBI Online - Generics and Biosimilars Initiative. Rituximab biosimilar successfully produced in plants [www.gabionline.net]. Mol, Belgium: Pro Pharma Communications International; [cited 2013 Jan 18]. Available from: www.gabionline.net/Biosimilars/News/Rituximab-biosimilar-successfully-produced-in-plants

Permission granted to reproduce for personal and educational use only. All other reproduction, copy or reprinting of all or part of any ‘Content’ found on this website is strictly prohibited without the prior consent of the publisher. Contact the publisher to obtain permission before redistributing.

Source: PlantForm

Research

Reaching ESG goals in pharmaceutical development

What is the future for the US biosimilar interchangeability designation

General

Samsung Bioepis wins Pyzchiva case; Regeneron patent rulings threaten foreign biosimilars

Chinese biosimilars go global: growth, partnerships, and challenges

Most viewed articles

The best selling biotechnology drugs of 2008: the next biosimilars targets

Global biosimilars guideline development – EGA’s perspective

Related content

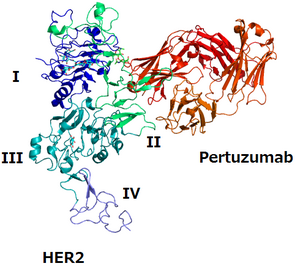

FDA approves Poherdy (first interchangeable pertuzumab) and Armlupeg (pegfilgrastim) biosimilars

EMA recommends approval for insulin glargine biosimilar Ondibta and denosumab biosimilar Osqay

FDA approves denosumab biosimilars Osvyrti and Jubereq, Boncresa and Oziltus

FDA approves aflibercept biosimilar Eydenzelt and label expansion for adalimumab biosimilar Yuflyma

FDA approves Poherdy (first interchangeable pertuzumab) and Armlupeg (pegfilgrastim) biosimilars

Biosimilars/News Posted 27/01/2026

EMA recommends approval for insulin glargine biosimilar Ondibta and denosumab biosimilar Osqay

Biosimilars/News Posted 16/01/2026

FDA approves denosumab biosimilars Osvyrti and Jubereq, Boncresa and Oziltus

Biosimilars/News Posted 07/01/2026

FDA approves aflibercept biosimilar Eydenzelt and label expansion for adalimumab biosimilar Yuflyma

Biosimilars/News Posted 05/12/2025

The best selling biotechnology drugs of 2008: the next biosimilars targets

Post your comment