New, alternative expression systems in various stages of development are showing their viability in large-scale protein manufacture. The economics and increased simplicity of these new platforms make them better alternatives to the currently dominant E. coli, yeast and CHO systems.

New expression systems create competitive advantage

Biosimilars/News

|

Posted 05/08/2009

0

Post your comment

0

Post your comment

According to Mr Eric Langer of BioPlan Associates, the question now is which of the more than 340 expression systems – and associated genetic engineering technologies – will become the next common industry platform. Today most pharmaceutical companies are considering the clinical, quality, and productivity implications of their expression system selections. Moreover, manufacturers consider how biosimilar competitors might use alternative technologies that could undercut the prices of innovative products.

The benefits of newer expression systems include improvements related to cost, such as increased protein yield and lower upfront investment. Furthermore, some offer more rapid scale-up, faster batch turn-around, and less costly supporting infrastructure or use totally disposable manufacturing equipment. Some incorporate fusion protein tag sequences that greatly facilitate simpler and cheaper downstream purification. Many simply offer higher yields with less equipment or much faster cell-line development, process scale-up, and testing, resulting in a higher speed to market. Some newer systems allow better control of expression aspects, including glycolysis. Such unique molecular modifications enable the design and selection of therapeutics with optimal properties, efficacy, and safety, in addition to allowing proprietary (patented or not) customisation of expressed proteins, providing a considerable barrier to the future development of competing biosimilar products.

Some novel expression systems are already well on track to become common industry platforms. For example, the Per.C6 expression system from Crucell and DSM Biologics is already having a major impact. This is one of the most advanced of the various human cell line alternatives to CHO cells, for which yields of over 30 g/L have been documented. Per.C6 will probably become a major platform for recombinant monoclonal antibody (mAb) manufacture. Many companies have already licensed Per.C6 for large-scale use and for internal production of therapeutic candidates. Other expression systems with high visibility and many licensees include the Pfenex Pseudomonas bacterium (commercialised by Dowpharma), and those of Invitrogen and GE. Merck acquired GlycoFi for over US$400 million (Euros 287.5 million) and is developing its first biosimilar with it. This ‘biobetter’ will be comparable to Amgen’s second-generation erythropoietin Aranesp, but is expected to have an improved therapeutic profile. Merck will also use GlycoFi to build in molecular modifications that will make it very difficult for those seeking to develop a competing biosimilar.

The expression systems in development include an incredible variety of organisms being transformed for recombinant protein expression. In coming years, industry will very likely be using multiple expression systems.

Source: BioPharm International, June 2009.

Research

Reaching ESG goals in pharmaceutical development

What is the future for the US biosimilar interchangeability designation

General

Samsung Bioepis wins Pyzchiva case; Regeneron patent rulings threaten foreign biosimilars

Chinese biosimilars go global: growth, partnerships, and challenges

Most viewed articles

The best selling biotechnology drugs of 2008: the next biosimilars targets

Global biosimilars guideline development – EGA’s perspective

Related content

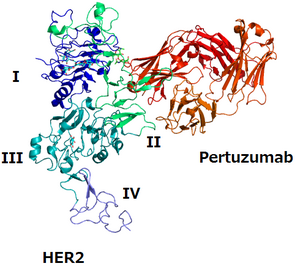

FDA approves Poherdy (first interchangeable pertuzumab) and Armlupeg (pegfilgrastim) biosimilars

EMA recommends approval for insulin glargine biosimilar Ondibta and denosumab biosimilar Osqay

FDA approves denosumab biosimilars Osvyrti and Jubereq, Boncresa and Oziltus

FDA approves aflibercept biosimilar Eydenzelt and label expansion for adalimumab biosimilar Yuflyma

FDA approves Poherdy (first interchangeable pertuzumab) and Armlupeg (pegfilgrastim) biosimilars

Biosimilars/News Posted 27/01/2026

EMA recommends approval for insulin glargine biosimilar Ondibta and denosumab biosimilar Osqay

Biosimilars/News Posted 16/01/2026

FDA approves denosumab biosimilars Osvyrti and Jubereq, Boncresa and Oziltus

Biosimilars/News Posted 07/01/2026

FDA approves aflibercept biosimilar Eydenzelt and label expansion for adalimumab biosimilar Yuflyma

Biosimilars/News Posted 05/12/2025

The best selling biotechnology drugs of 2008: the next biosimilars targets

Post your comment