In the early days, most monoclonal antibody (MAb) therapies required high dosages, as pointed out by Ms Gail Dutton in a Genetic Engineering & Biotechnology News Feature Article on 15 February 2010 (see also Monoclonal antibodies modelling - predictive analytics, Improving monoclonal antibody production - antibody-drug conjugate technology and Modern monoclonal antibody production - focus on quality by design, timelines, cost)

How to tackle overcapacity in monoclonal antibody production

Biosimilars/News

|

Posted 09/03/2010

0

Post your comment

0

Post your comment

Dr Günter Jagschies, Senior Director R & D of GE Healthcare Life Sciences told Ms Dutton that to meet those needs, bioreactor output improved about 10-fold, so that optimised bioreactors today produce 3–4 grams per litre. “Currently installed capacity, combined with that being built, will yield a 120-ton capacity, which is six-fold more than is needed. Some new plants won’t be put into operation and others are probably cancelling their building projects,” he added.

Ms Dutton writes that several companies are now building smaller facilities to reduce capital outlay and are working with contract manufacturing organisations (CMOs) as needed. “But, for companies with excess capacity in existing facilities, the options are to use the space to produce other proteins in smaller scales, to use disposable set-ups, and to bring in other products if you can,” Dr Jagschies told her, recognising that production lines and bioreactors are not necessarily interchangeable.

“The issue of stainless steel versus disposable equipment is irrelevant. Instead, flexibility is the issue. You have to have several separate production lines and lines at different scales to hold different organisms, and to work in parallel. At 1,000 to 2,000 liters you can do that with roll-in/roll-out capacity,” Dr Jagschies said.

He explained that bioreactor advances have created a bottleneck downstream, where purification steps are not providing higher capacities from new resins. “People take this into consideration,” Dr Jagschies continued. “They are always looking for increased productivity with newly developed downstream tools that can resolve capacity bottlenecks.”

Reference:

Gail Dutton. Trends in Monoclonal Antibody Production - With Capacity Issues Resolved, Firms Direct Attention to Quality, Timelines, and Cost. Genetic Engineering & Biotechnology News Vol. 30, No. 4. 2010 February 15.

Source: Genetic Engineering & Biotechnology News

Research

Reaching ESG goals in pharmaceutical development

What is the future for the US biosimilar interchangeability designation

General

Samsung Bioepis wins Pyzchiva case; Regeneron patent rulings threaten foreign biosimilars

Chinese biosimilars go global: growth, partnerships, and challenges

Most viewed articles

The best selling biotechnology drugs of 2008: the next biosimilars targets

Global biosimilars guideline development – EGA’s perspective

Related content

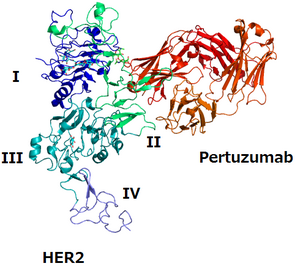

FDA approves Poherdy (first interchangeable pertuzumab) and Armlupeg (pegfilgrastim) biosimilars

EMA recommends approval for insulin glargine biosimilar Ondibta and denosumab biosimilar Osqay

FDA approves denosumab biosimilars Osvyrti and Jubereq, Boncresa and Oziltus

FDA approves aflibercept biosimilar Eydenzelt and label expansion for adalimumab biosimilar Yuflyma

FDA approves Poherdy (first interchangeable pertuzumab) and Armlupeg (pegfilgrastim) biosimilars

Biosimilars/News Posted 27/01/2026

EMA recommends approval for insulin glargine biosimilar Ondibta and denosumab biosimilar Osqay

Biosimilars/News Posted 16/01/2026

FDA approves denosumab biosimilars Osvyrti and Jubereq, Boncresa and Oziltus

Biosimilars/News Posted 07/01/2026

FDA approves aflibercept biosimilar Eydenzelt and label expansion for adalimumab biosimilar Yuflyma

Biosimilars/News Posted 05/12/2025

The best selling biotechnology drugs of 2008: the next biosimilars targets

Post your comment